Henan Zhongfu Industrial Co., Ltd

HENAN ZHONGFU INDUSTRIAL CO., LTD

Henan Zhongfu Industrial Co., Ltd, located in Gongyi City, Henan Province. It is an international high-end aluminum alloy new material enterprise with aluminum deep processing as the main body and supporting high-efficiency collaborative coal electricity aluminum and green hydropower aluminum dual industry chains. It was listed on the Shanghai Stock Exchange in 2002. The company currently has total assets of 23.1 billion yuan, with an annual production capacity of 690000 tons of aluminum deep processing, 750000 tons of electrolytic aluminum (including 500000 tons of green hydropower aluminum and 250000 tons of thermal power aluminum), 150000 tons of carbon, 900000 kilowatts of electricity, and 2.25 million tons of raw coal. It ranks among the top 500 private manufacturing enterprises in China. The controlling shareholder Yulian Group ranks 271st in the 2023 "Top 500 Chinese Manufacturing Enterprises", 264th in the 2023 "Top 500 Chinese Private Enterprises", 184th in the "Top 500 Chinese Manufacturing Private Enterprises", 16th in the "Top 100 Henan Enterprises", and 8th in the "Top 100 Henan Manufacturing Enterprises".

Zhongfu Industrial's high-end aluminum manufacturing is based on the goal of "international first-class and domestic leading", mainly using international first-class equipment such as German Westmark, Siemens, ABB, and Danieli. The company's products include can body materials, can cover materials, pull ring materials, aluminum foil for new energy battery aluminum-plastic film, aluminum foil for new energy battery current collector, aluminum foil for new energy battery tab, high-end double zero aluminum foil wool, high surface anodizing materials for 3C electronic products, automotive board materials, high-performance plates for oil tank trucks, etc. The end products can be widely used in rapid consumer goods packaging fields, such as cans, Tetra Pak bags, sterile bags, new energy vehicles, and consumer electronics. At present, our products are exported to over 110 factories in more than 40 countries around the world. Our core product, the aluminum alloy strip for easy-pull lids, has a global market share of 10%, and the domestic market share for this product is over 30%.

Based on the green and sustainable development strategy, Zhongfu Industrial has built and put into operation a cross provincial transfer project with an annual production capacity of 500000 tons of electrolytic aluminum in Guangyuan, Sichuan, forming a new industrial layout of green "hydropower aluminum". Currently, green hydropower aluminum production capacity accounts for nearly 70%. The company is accelerating the construction of photovoltaic projects and a 500000 ton aluminum recycling project, achieving the "greening" of energy and raw materials, accelerating the development and layout of the new energy market, and realizing the "greening" of products. The company actively builds a green, low-carbon, and zero emission park, accelerating the implementation of green and low-carbon projects including comprehensive resource utilization, equipment and facility technology transformation, etc., to achieve the organic combination of energy transformation, industrial development, and ecological environmental protection. Subsidiary Zhongfu Aluminum Industry has successfully passed the A-level environmental performance evaluation. Guangyuan Linfeng Aluminum and Electric Co., Ltd. has been rated as a benchmark enterprise for energy conservation and carbon reduction and a "leader" in energy efficiency in key energy consuming industries. Zhongfu High precision Aluminum Company has been recognized as a national "green factory". Sichuan Zhongfu Company's 298000 ton production capacity has obtained the first batch of green aluminum certification in the industry and has obtained the Sichuan Province Clean Energy Consumption Certificate.

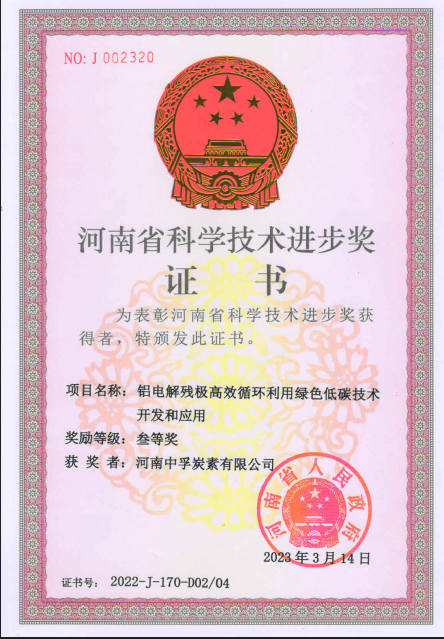

Zhongfu Industrial adheres to technological innovation, relying on innovation platforms and talent teams such as the "National Recognized Enterprise Technology Center", "Henan Province High Efficiency Aluminum Based New Material Innovation Center", and "Henan Province High tech Enterprise", independently researching and developing the "Large scale Aluminum Electrolysis Series Continuous Cutting Technology", which has won the second prize of National Science and Technology Invention; The National Science and Technology Support Program project "Low temperature and Low voltage Aluminum Electrolysis New Technology" has enabled China's energy-saving technology for electrolytic aluminum to reach the world's leading level; The overall project of "Research and Development of Key Energy saving Technologies for Aluminum Electrolytic Cells" has reached the international leading level; The "Comprehensive Utilization Technology of Aluminum Electrolytic Cell Overhaul Slag Resources" led by the implementation has solved the world's problem of hazardous solid waste resource utilization of aluminum electrolytic cell overhaul slag, and will play a demonstration and leading role in the industry; Mastered the technology of mass production of 0.208mm ultra-thin can lid material and developed 0.235mm ultra-thin can body material; Participated in drafting and formulating multiple national, provincial, and municipal group standards, and obtained national patent certification for multiple achievements. At the same time, the company continuously improves its incentive mechanism for technological innovation, integrating intelligent and digital means to provide technological support for high-quality development of the enterprise. In 2023, Zhongfu Industrial was rated as a national intellectual property advantage enterprise, and its subsidiaries Guangyuan Zhongfu High precision Aluminum Company and Guangyuan Linfeng Aluminum and Electric Company were recognized as "national high-tech enterprises". Zhongfu High precision Aluminum Company was rated as a national level specialized and new "little giant" enterprise.

Looking towards the future, Zhongfu Industrial will adhere to the development philosophy of "strengthening, optimizing, refining, and lasting", uphold the corporate mission of "focusing on industry and contributing to society", anchor the direction of green, intelligent, and digital development, continuously optimize the industrial structure and energy structure, continuously improve management level, enhance employee welfare, and strive to build a globally leading, green, low-carbon high-end aluminum enterprise, making new and greater contributions to promoting the sustainable and healthy development of China's aluminum industry.

Subsidiary Introduction

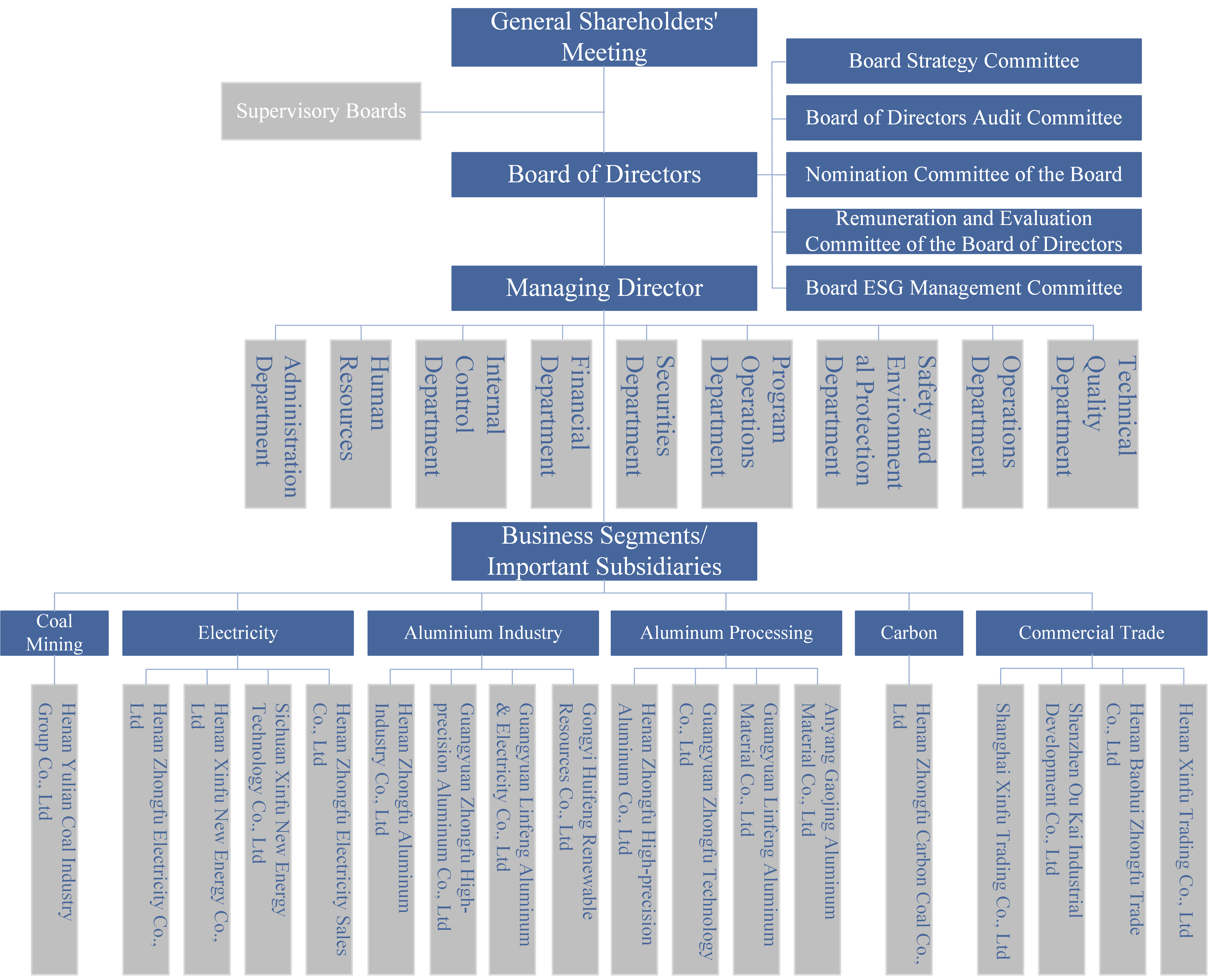

Organizational Structure

Research Ability

Foreword

Technological innovation is the core driving force for enterprise development and the key to adapting to rapidly changing market environments and meeting customer needs. Among the five major challenges facing global technological innovation, our company always adheres to innovation as the guide, constantly explores new technologies and products, and is committed to solving technological bottlenecks and market demands in the industry. We deeply understand that only through continuous innovation can we stand invincible in the fierce market competition. Therefore, we have established a sound innovation mechanism and strengthened cooperation with domestic and foreign industry, academia, and research institutions to jointly promote the development of scientific and technological innovation. In the face of future challenges, we always adhere to the principle of "one body, two wings", placing technological innovation at the logical starting point and core position of leading enterprise development. We deeply implement the overall technological innovation development strategy of innovation driven, technology driven, management supported, and talent strong enterprises, and build a fully staffed, all-round, and full process innovation ecosystem.

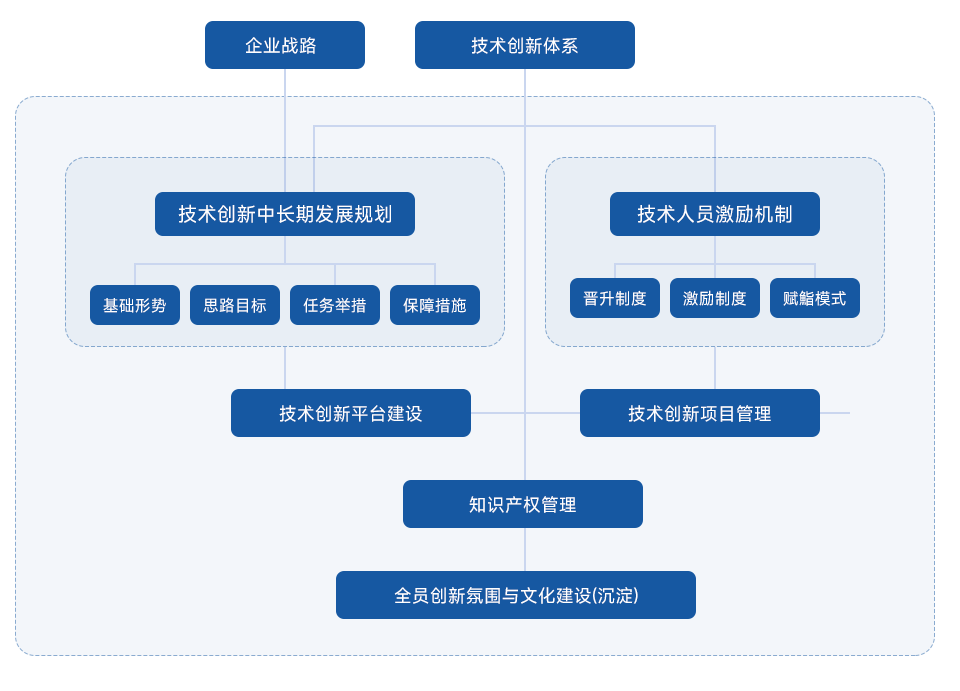

Innovation System

According to the national 14th Five Year Plan and the 2035 long-term goals, the group company actively implements the requirements of the dual carbon economy policy and clarifies the direction of green, digital, and intelligent development. In this context, Yulian Group has collaborated with Zhengzhou University to develop a medium - and long-term development plan for technological innovation, establish a technology innovation system for the group company, formulate management measures for the promotion of professional technical levels of engineering and technical personnel, improve technology innovation projects, intellectual property management methods, and incentive measures for engineering and technical personnel innovation, build a technology innovation information platform, and create a culture of innovation among all employees within the group, laying the foundation for achieving high-quality, green, and low-carbon development goals.

Technology Innovation Platform: National Recognized Enterprise Technology Center, Henan Province High Efficiency Aluminum based New Material Innovation Center, Henan Province Aluminum Smelting Engineering Technology Research Center, Institute Enterprise Cooperation (Shanghai Jiao Tong University, Central South University, etc.)

Technical Team

The group company has nearly 600 engineering and technical personnel, including 2 doctoral students, 98 master's students, 5 professor level senior engineers, 29 senior engineers, and 230 intermediate engineers. Technicians are rooted in the front line of production, solving production problems through practical innovation, accumulating rich practical experience in their respective professional fields, and providing strong intellectual support for promoting industrial upgrading< br>

Adhere to the combination of independent innovation and external joint development, continuously promote the "company+research institute+university" cooperation model in various industrial sectors, fully leverage the synergistic effect between industry, academia, research and application, connect research institutes, universities and high-tech enterprises in small and medium-sized enterprises through platforms such as the National Enterprise Technology Center and the Henan Province High Efficiency Aluminum based New Materials Innovation Center, integrate their respective advantages, and promote common development.

Technological innovation achievements

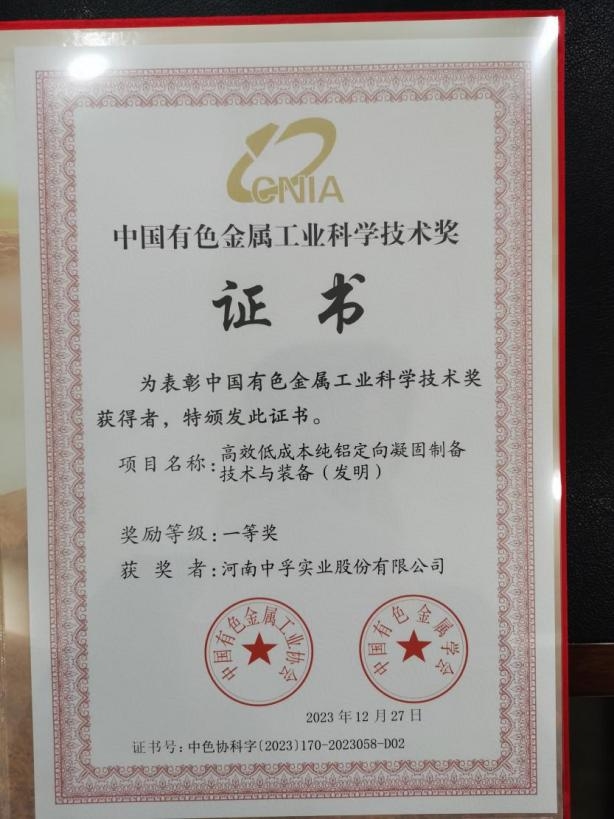

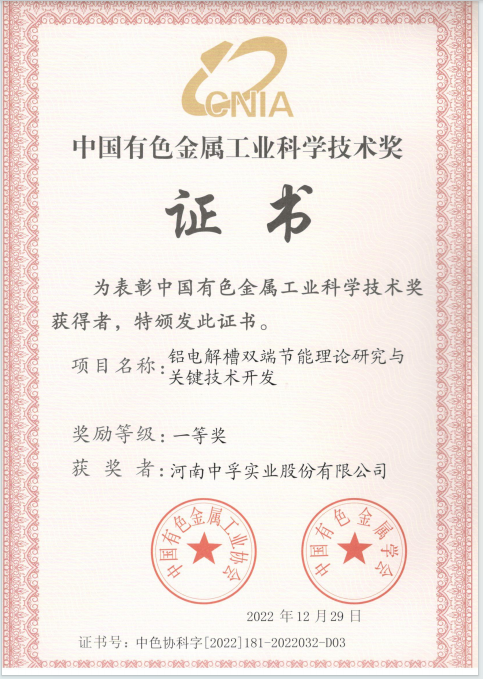

Technology project category: The "Research and Development of Key Energy saving Technologies for Aluminum Electrolysis Double End" project, which cooperates with Zhengzhou University, Zhengzhou Light Metallurgy Alloy and other units, won the first prize of China Nonferrous Metals Science and Technology Progress Award, realizing the efficient utilization of large-scale low-temperature thermal energy resources for electrolytic aluminum. It has significant economic, environmental and social benefits, and the overall technology has reached the international leading level, which is of great significance for solving common problems in the domestic aluminum industry.

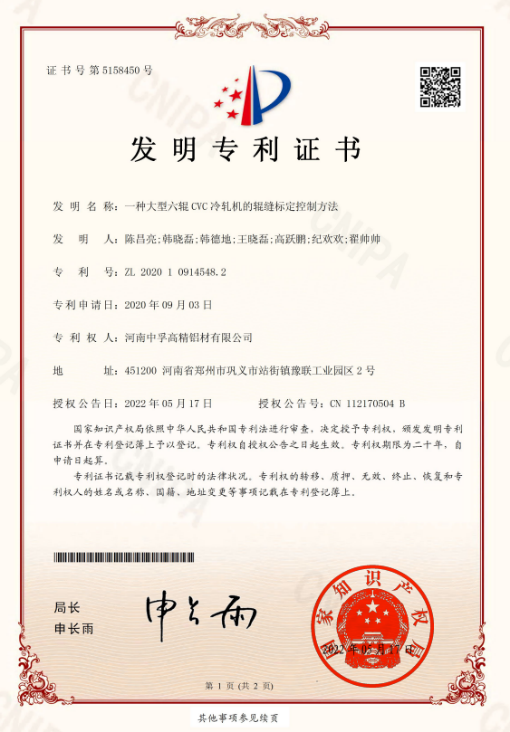

Patents: As of now, Yulian Group has obtained a total of 537 authorized patents, including 59 invention patents and 1 national patent gold award< br> Standards: As of now, I have participated in the preparation and revision of 17 standards, including 1 national standard, 1 industry standard, and 15 group standards.

Honor

Henan strategic emerging industry enterprise T100

2024

Transformation and innovation outstanding enterprise

2024

Customs AEO advanced certification enterprise

2024

National green factory

2023

quality improvement "T10" demonstration leading advanced units

2023

"Green electric aluminum" product procurement

2023

Clean energy consumption certificate

2023

T500 private manufacturing enterprises in China

2022